Schottky Diode: Understanding Its Function and Applications

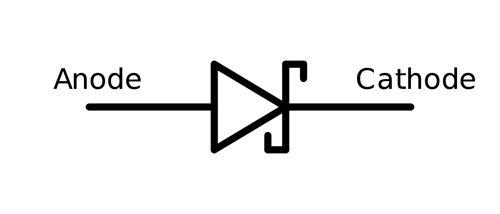

Schottky diode is a type of diode that is widely used in various electronic applications. It is named after the German physicist Walter H. Schottky, who first discovered this semiconductor diode. The Schottky diode is also known as a Schottky barrier diode or a hot-carrier diode. The symbol of the Schottky diode is shown below.

The Schottky diode is formed by the junction of a metal and a semiconductor. It has a low forward voltage drop and a very fast switching action. The low forward voltage drop makes it ideal for use in applications where energy efficiency is important. The fast switching action makes it useful in applications that require high-speed switching, such as in power supplies, inverters, and rectifiers.

Key Takeaways

- Schottky diode is a semiconductor diode named after the German physicist Walter H. Schottky.

- It is formed by the junction of a metal and a semiconductor and has a low forward voltage drop and fast switching action.

- Schottky diodes are widely used in various applications that require high-speed switching and energy efficiency.

Basics of Schottky Diode

A Schottky Diode is a semiconductor device that is widely used in various electronic circuits, including voltage clamping, rectification, and switching applications. It is a type of metal-semiconductor diode that has a low forward voltage drop and a very fast switching speed.

Unlike other diodes, a Schottky diode is formed by the junction of a semiconductor material with a piece of metal, typically aluminum or platinum. This junction creates a Schottky barrier, which is a potential energy barrier that prevents the flow of electrons from the metal to the semiconductor. When a forward voltage is applied across the Schottky diode, the barrier is lowered, allowing current to flow through the device.

One of the key advantages of Schottky diodes is their low forward voltage drop, typically around 0.3 to 0.5 volts. This makes them ideal for use in circuits where low power loss is critical. Additionally, Schottky diodes have a very fast switching speed, making them suitable for high-frequency applications.

Schottky diodes are available in a range of sizes and power ratings, from small signal devices that can handle a few milliamps to high-power devices that can handle tens or even hundreds of amps. They are also available in a range of package types, including surface mount packages, through-hole packages, and stud mount packages.

Overall, Schottky diodes are a versatile and widely used semiconductor device that offers low power loss, fast switching speed, and a range of sizes and power ratings. They are an essential component in many electronic circuits and are used in a variety of applications, including power supplies, voltage regulators, and rectifiers.

Working Principle

A Schottky diode is a semiconductor diode that has a low forward voltage drop and a fast switching action. It is also known as a hot carrier diode or a Schottky barrier diode. The diode is formed by the junction of a semiconductor with a metal. The metal acts as a cathode, and the semiconductor acts as an anode.

The Schottky diode works based on the principle of the Schottky barrier. When a metal comes in contact with a semiconductor, there is a difference in the work function between the two materials. This difference in the work function creates a potential barrier at the interface, known as the Schottky barrier. The height of the barrier depends on the materials used and the doping level of the semiconductor.

When a voltage is applied across the Schottky diode, the current flows from the metal to the semiconductor. Since the Schottky barrier is lower than the potential barrier in a p-n junction diode, the forward voltage drop across the Schottky diode is lower. This results in a faster switching action and lower power loss.

The Schottky diode is widely used in high-speed switching applications, such as in rectifiers, clippers, and clamps. It is also used in power supplies, voltage regulators, and RF applications. The Schottky diode can handle high-frequency signals and has a low reverse recovery time, making it suitable for use in high-frequency circuits.

In summary, the Schottky diode works based on the principle of the Schottky barrier. It has a low forward voltage drop and a fast switching action, making it suitable for use in high-speed switching applications.

Construction of Schottky Diode

A Schottky diode is a semiconductor device that is formed by a junction of a semiconductor and a metal, typically gold, silver, molybdenum, tungsten, or platinum. The semiconductor used in a Schottky diode is usually an N-type semiconductor, with gallium being the most commonly used material.

Unlike a regular p-n junction diode, a Schottky diode's junction is formed between a metal and a semiconductor, and not between two semiconductors. This allows it to have a lower forward voltage drop and a faster switching action.

The construction of a Schottky diode involves the following steps:

- A thin layer of metal is deposited on top of an N-type semiconductor substrate.

- The metal and semiconductor are then heated to a high temperature to form a thin layer of intermetallic compound at the junction. This process is called alloying.

- The metal and semiconductor are then allowed to cool down, and a thin layer of oxide is formed on the metal surface through a process called oxidation.

- The oxide layer serves as a barrier to prevent current flow in the reverse direction.

The resulting Schottky diode has a metal-semiconductor junction that forms a rectifying contact, allowing current to flow in one direction while blocking it in the other. The unique construction of a Schottky diode allows it to have a faster response time and lower forward voltage drop compared to traditional p-n junction diodes.

Overall, the construction of a Schottky diode is a relatively simple process that utilizes standard semiconductor fabrication techniques such as alloying, diffusion, and oxidation to form its junctions.

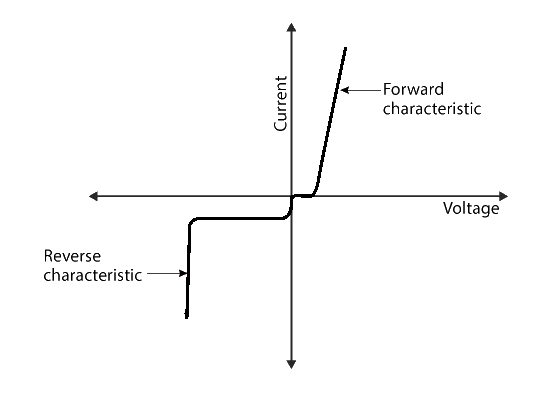

VI Characteristics

One prominent characteristic is their remarkably low forward voltage drop compared to p-n diodes. This lower voltage drop results from their metal-semiconductor junction construction, enabling Schottky diodes to efficiently rectify signals with reduced energy loss. Another notable trait is their rapid switching speed and minimal reverse recovery time. The absence of minority carrier storage in the metal-semiconductor junction grants Schottky diodes the ability to swiftly switch between conducting and non-conducting states, making them suitable for high-frequency applications and high-speed rectification tasks. The lower junction capacitance of Schottky diodes, attributed to their structure, further enhances their performance in high-frequency circuits, ensuring improved signal integrity and reduced signal degradation. However, it's important to consider their temperature sensitivity; as temperature increases, Schottky diodes can exhibit elevated reverse leakage current, impacting their behavior in elevated temperature environments. Despite their advantages, particularly in radio frequency (RF) and microwave circuits for tasks like frequency mixing and signal detection, Schottky diodes may experience increased power loss at higher voltages due to their lower forward voltage drop. As with any semiconductor component, understanding these characteristics is essential for selecting the right diode type for a given application.

Characteristics

Schottky diodes have several unique characteristics that set them apart from other types of diodes. Here are some of the key characteristics of Schottky diodes:

- Low forward voltage drop: Schottky diodes have a very low forward voltage drop, typically around 0.3 volts. This means that they can conduct current more efficiently than other types of diodes, which helps to reduce power consumption and improve overall system efficiency.

- Fast switching speed: Schottky diodes also have a very fast switching speed, typically in the range of nanoseconds. This makes them ideal for use in high-frequency applications, such as switching power supplies and RF circuits.

- Low reverse recovery time: Schottky diodes have a very low reverse recovery time, which means that they can switch from forward to reverse bias very quickly. This makes them ideal for use in applications where fast switching speeds are required.

- High-temperature tolerance: Schottky diodes are also highly tolerant of high temperatures, making them suitable for use in a wide range of environments.

- Low capacitance: Schottky diodes have a low capacitance, which makes them ideal for use in high-frequency applications where low parasitic capacitance is critical.

Overall, Schottky diodes are highly versatile components that can be used in a wide range of applications. Their low forward voltage drop, fast switching speed, and low reverse recovery time make them ideal for use in high-frequency circuits, while their high-temperature tolerance and low capacitance make them suitable for use in a wide range of environments.

Applications and Uses

Schottky diodes have a wide range of applications due to their unique properties, including low forward voltage drop, fast switching speed, and low reverse recovery time. Here are some of the most common applications of Schottky diodes:

Power Rectification

Schottky diodes are commonly used as rectifiers in power supplies. They are particularly useful in applications where high efficiency and low voltage drop are required. For example, they can be used to rectify the output of a solar panel, where a low forward voltage drop is essential to maximize the power output.

RF and Microwave Applications

Schottky diodes are widely used in RF and microwave circuits due to their fast switching speed and low noise characteristics. They can be used as detectors, mixers, and frequency multipliers in these circuits. They are also used in high-frequency circuits for automatic tuning, frequency modulation, and equalization.

Automotive Applications

Schottky diodes are commonly used in automotive applications, particularly in alternator rectifiers and voltage regulators. They are also used in electronic control units (ECUs) for engine management and other applications.

Computer and Electronic Applications

Schottky diodes are used in various electronic applications, including logic gates, digital circuits, and memory devices. They are also used in power management circuits, where their low forward voltage drop and high efficiency make them ideal for applications such as voltage regulators and DC-DC converters.

Other Applications

Schottky diodes are used in a variety of other applications, including:

- Battery charging circuits

- Switching power supplies

- LED drivers

- Audio amplifiers

- Voltage clamps

Overall, Schottky diodes are versatile and widely used in a variety of applications due to their unique properties.

Advantages and Disadvantages

Schottky diodes offer several advantages over other types of diodes, but they also have some disadvantages that should be taken into consideration.

Advantages

- Low forward voltage drop: Schottky diodes have a lower forward voltage drop compared to other diodes, which results in less power loss and increased efficiency. This makes them ideal for use in power supplies, voltage regulators, and other applications where energy efficiency is important.

- High switching speed: Schottky diodes have a very fast switching speed due to the absence of a charge storage period. This makes them ideal for use in high-frequency circuits and applications where fast switching speeds are required.

- Negligible storage time: Schottky diodes have a very short storage time, which means that they can switch off very quickly. This makes them ideal for use in pulse circuits, where a fast response time is required.

- Closer to ideal than other diodes: Schottky diodes have a forward voltage drop (VF), reverse-recovery time (trr), and junction capacitance (CJ) that are closer to ideal than other diodes. This makes them well-suited for use in high-performance circuits and applications where accuracy and precision are important.

Disadvantages

- High reverse leakage current: Schottky diodes have a higher reverse leakage current compared to other diodes, which increases with temperature. This means that they may not be suitable for use in applications where low leakage current is important.

- Lower reverse voltage rating: Schottky diodes have a lower reverse voltage rating compared to other diodes. This means that they may not be suitable for use in applications where high reverse voltage is required.

- Limited temperature range: Schottky diodes have a limited temperature range compared to other diodes. This means that they may not be suitable for use in applications where high-temperature stability is required.

Overall, Schottky diodes offer several advantages over other diodes, but they also have some disadvantages that should be taken into consideration when selecting a diode for a particular application.

Comparison with Other Diodes

Schottky diodes differ from other diodes in several ways. Here are some of the key differences:

Schottky Diode vs. PN Junction Diode

The most common type of diode is the PN junction diode. The PN junction diode is made by doping a semiconductor with impurities to create regions of N-type and P-type material. When a voltage is applied across the diode, current can flow in one direction but not the other. The PN junction diode has a higher forward voltage drop than the Schottky diode. The forward voltage drop of a Schottky diode is typically between 0.15V and 0.45V, while the forward voltage drop of a PN junction diode is typically between 0.6V and 0.7V.

Schottky Diode vs. Zener Diode

Zener diodes are designed to operate in the reverse breakdown region. When a voltage is applied in the reverse direction, the Zener diode maintains a constant voltage across its terminals. This makes Zener diodes useful for voltage regulation. Schottky diodes are not designed to operate in the reverse breakdown region and should not be used for voltage regulation.

Schottky Diode vs. Fast Recovery Diode

Fast recovery diodes (FRDs) are designed to have a short reverse recovery time. This means that they can switch from conducting to non-conducting faster than other diodes. Schottky diodes have a very short reverse recovery time and are often used in high-speed switching applications where fast switching times are critical.

Schottky Diode vs. Silicon Carbide Diode

Silicon carbide (SiC) diodes have a higher breakdown voltage and can operate at higher temperatures than Schottky diodes. SiC diodes also have lower forward voltage drop and lower reverse recovery time than Schottky diodes. However, SiC diodes are more expensive than Schottky diodes and may not be necessary for all applications.

Selection Criteria

When selecting a Schottky diode for a particular application, several factors should be taken into consideration to ensure optimal performance. Some of the critical selection criteria include:

Forward Voltage

The forward voltage of a Schottky diode is the voltage drop across the diode when it is forward-biased. It is an essential parameter to consider when selecting a Schottky diode for a specific application. The forward voltage of a Schottky diode is typically lower than that of a standard PN junction diode, making it ideal for use in low-voltage applications.

Reverse Voltage

The maximum reverse voltage that a Schottky diode can withstand without breakdown is another critical selection criterion. The reverse voltage rating of a Schottky diode must be higher than the maximum voltage that it will be exposed to during operation.

Current Rating

The current rating of a Schottky diode is the maximum amount of current that it can handle without thermal breakdown. When selecting a Schottky diode, it is crucial to choose one with a current rating that is higher than the maximum current that it will be subjected to during operation.

Junction Capacitance

The junction capacitance of a Schottky diode is the capacitance between the anode and the cathode. It is an essential parameter to consider in high-frequency applications. A Schottky diode with a lower junction capacitance is preferable for high-frequency applications.

Package Type

The package type of a Schottky diode is another critical selection criterion. The package type determines how the diode is mounted on a printed circuit board (PCB). Different package types have different thermal characteristics, and it is essential to choose a package type that is suitable for the application.

Operating Temperature Range

The operating temperature range of a Schottky diode is another critical selection criterion. The operating temperature range specifies the minimum and maximum temperatures at which the diode can operate reliably. It is essential to choose a Schottky diode with an operating temperature range that is suitable for the application.

In summary, when selecting a Schottky diode for a particular application, it is essential to consider the forward voltage, reverse voltage, current rating, junction capacitance, package type, and operating temperature range. By carefully considering these selection criteria, one can ensure the optimal performance of the Schottky diode in the chosen application.

Future Trends

Schottky diodes have been around for over a century, and they continue to be an important component in modern electronic devices. As technology advances, so too do the applications for Schottky diodes. Here are some future trends that are likely to shape the development of Schottky diodes in the coming years.

Wide Bandgap Materials

One of the most significant trends in Schottky diode development is the use of wide bandgap materials, such as silicon carbide (SiC) and gallium nitride (GaN). These materials have higher breakdown voltages and faster switching speeds than traditional silicon-based diodes, making them ideal for high-power and high-frequency applications. As these materials become more widely available and cost-effective, they are expected to replace silicon-based diodes in many applications.

2D Materials

Another area of research is the use of two-dimensional (2D) materials, such as graphene and molybdenum disulfide (MoS2), in Schottky diodes. These materials have unique electronic and mechanical properties that make them ideal for applications such as flexible electronics and sensors. However, the challenge is to integrate these materials into practical devices while maintaining their desirable properties.

Environmental Monitoring

Schottky diodes are also finding new applications in environmental monitoring. For example, they can be used as gas sensors to detect pollutants and other harmful gases in the air. As the need for environmental monitoring increases, Schottky diodes are likely to play an increasingly important role in this field.

Higher Efficiency

Finally, there is a growing demand for more efficient electronic devices. Schottky diodes can help to achieve this goal by reducing power losses and improving energy efficiency. As a result, there is a focus on developing new materials and device structures that can further improve the efficiency of Schottky diodes.

Overall, the future of Schottky diodes looks bright, with new materials, applications, and device structures being developed all the time. As technology continues to advance, Schottky diodes are likely to remain an important component in electronic devices for years to come.